This is a SEO version of EIF_CIP case studies. Click here to view full version

« Previous Page Table of Contents Next Page »Are residues from cleantech product manufacturing discarded, buried at the bottom of the oceans or recycled for further use? Recycling is the option chosen by Metallkraft.

The company converts exhausted slurry from the wafer cutting process used for solar panel production into a re-usable product. It then supplies “clean” slurry, which has fully regained its cutting abilities, back to the wafer manufacturer. Depending on the cutting process, Metallkraft can recover almost 100% of the slurry for re-use. The company’s solution turns hazardous waste into safe materials using no added chemicals and emission-free processes; it generates minimal waste and reduced energy consumption.

“Our founder, Dr. Knut Henriksen, has been developing slurry recovery technologies since the 1990s, so we are commercially well established in our country. The Capricorn Cleantech Fund team provided valuable CIP fnancial support for the international expansion of our company. Its knowledge of the photovoltaic sector and its extensive network of contacts were key elements for our growth”, explains Metallkraft’s Managing Director Gunnar Kulia.

By recycling the used slurry, Metallkraft not only allows the wafer manufacturers to cut their costs by around 50% but also helps them reduce their environmental footprint.

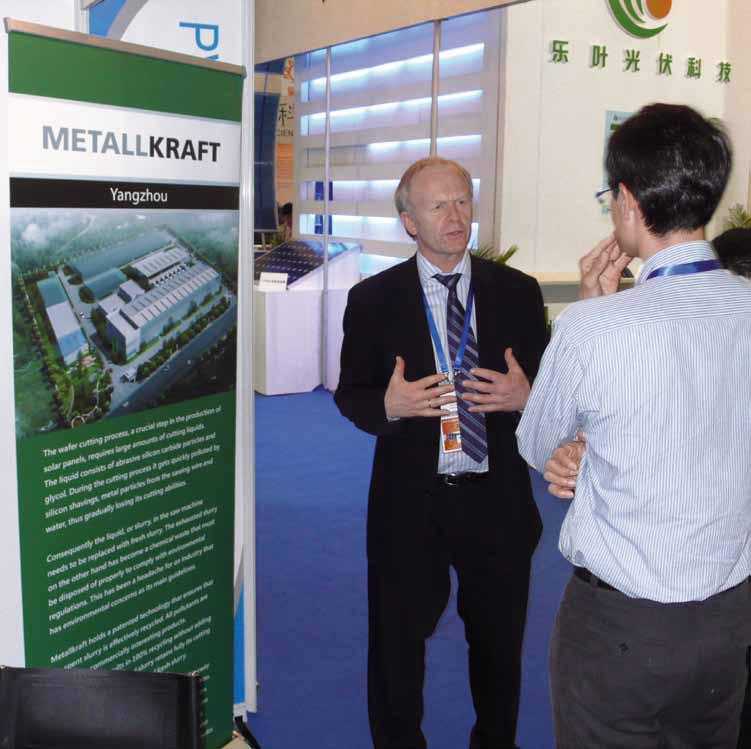

Company: Metallkraft AS, Kristiansand

Type of business: Slurry recycling EU-supported investment through Capricorn Cleantech Fund

47

Norway

Making clean energy cleaner

This is a SEO version of EIF_CIP case studies. Click here to view full version

« Previous Page Table of Contents Next Page »